Business success depends heavily on the efficiency of supply chain operations. The supply chain operates as an invisible force that drives all business operations. Each step in the supply chain process plays an essential role, from material acquisition to product delivery. Supply chains often become complicated to manage. Delays happen. Costs rise. Mistakes appear unexpectedly. The discovery of innovative supply chain enhancement methods creates significant business advantages.

The following five straightforward methods will transform your supply chain into a faster and smarter operation with enhanced efficiency.

Strengthen Relationships with Your Suppliers

Suppliers often get treated as basic components within the supply chain structure. Suppliers function as strong partners who can help businesses achieve their goals. Businesses that establish trust with their suppliers experience enhanced communication between both parties. Problems are solved faster. The process can lead to better deals for both parties.

Strong relationships prove beneficial during unexpected supply chain challenges. A supplier who has earned your trust will provide exceptional service when supply runs short. Suppliers can provide valuable information that helps improve manufacturing processes. The early detection of hidden problems becomes possible through open dialogue. This avoids last-minute chaos.

The combination of routine meetings with truthful assessments and mutual performance targets creates significant progress. The process operates more efficiently when all parties experience mutual support and understanding.

Keep Inventory Lean but Ready

Stocking too much inventory can tie up money and space. But too little can cause big delays. The secret is finding balance. This is where lean inventory management comes in.

The idea is to keep what’s needed and nothing more. Use real-time data to track how fast products move. Adjust orders based on demand. Don’t let goods sit on shelves for months.

Smarter systems can predict trends. This helps avoid overstocking or shortages. Some businesses use automation to reorder supplies before running out. It takes the guesswork out of the process.

When inventory is balanced, businesses save money and work more efficiently.

Use Local Resources When Possible

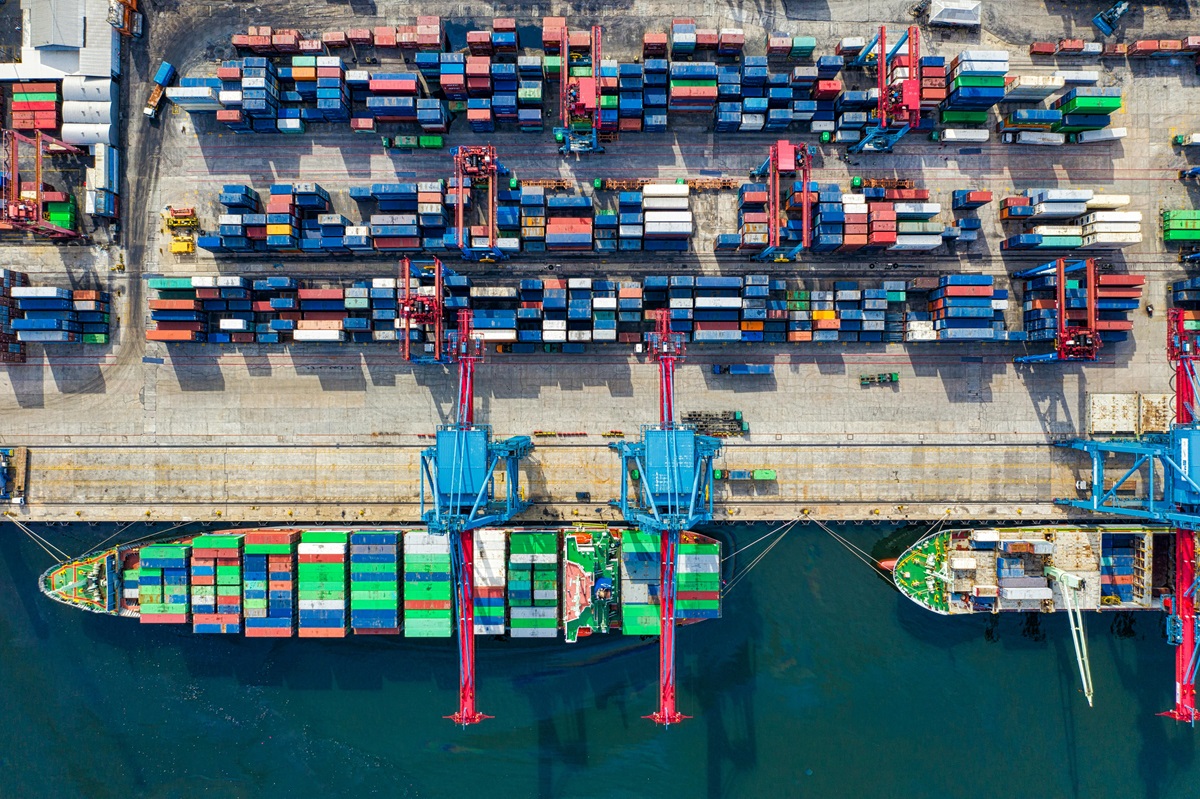

Shipping goods across the globe takes time. It also adds cost and risk. By looking closer to home, companies can speed up deliveries and cut expenses.

Local suppliers can respond faster. They may offer smaller, more flexible orders. There’s less chance of delays at ports or border checks.

This doesn’t mean giving up on global sources. However, adding local options can reduce stress on the system. It also helps in times of disruption. Whether it’s a pandemic, a storm, or supply shortages, having nearby sources can be a lifesaver.

One example is how some manufacturers are shifting to regional partners for parts like sheet metal stamping. It keeps production moving without relying on overseas deliveries.

Make the Most of Technology

Technology doesn’t have to be complex to be useful. Simple tools can bring big improvements. Even a basic tracking system can help spot delays early.

Modern software allows companies to see what’s happening at each stage. From raw materials to delivery, everything is visible. This helps find where time or money is being wasted.

Some companies use dashboards to track shipments in real time. Others rely on data analytics to understand patterns. These insights help you plan better and respond faster.

Technology also helps teams work together. Shared platforms let everyone, from warehouse staff to delivery drivers, stay on the same page. Mistakes go down. The speed goes up.

Train People, Not Just Machines

At the heart of every supply chain are people. Machines and software can do a lot, but they need the right people behind them.

When teams understand the whole process, they work smarter. Training helps them spot problems early. It also shows them how their role fits into the bigger picture.

Even a few hours of extra learning can make a difference. Whether it’s how to use a new system or handle goods more safely, the payoff is real.

When workers feel prepared and valued, their performance improves. Morale goes up. Turnover goes down. And the entire supply chain benefits.

Conclusion

Optimizing a supply chain isn’t about giant overhauls. It’s about small, smart choices. Building strong relationships. Keeping inventory in check. Thinking local. Using the right tech. And making sure people are ready to perform.

Each step adds up. Together, they create a system that runs smoother, faster, and with fewer surprises. A better supply chain means fewer delays, lower costs, and happier customers. In today’s fast-moving world, that kind of edge is priceless.