You need the right software and machines. You also must choose the right materials for 3D printing with Silhouette machines. It is used to create high-quality, detailed, and durable designs. 3D printing software affects strength, flexibility, look, and suitability for its purpose. The Silhouette Design Store offers many options to meet your needs. PLA is a popular filament type. It is easy to use and eco-friendly. ABS filament is tough and resistant, ideal for heat-resistant projects.

TPU filament is flexible and durable. Wood-infused or metallic PLA adds an artistic touch to your projects. The Silhouette machine provides unlimited possibilities for 3D printing. Let’s explore some excellent materials that can inspire your 3D printing projects. These will also improve the results with your Silhouette machine.

Understanding 3D Printing with Silhouette Machines

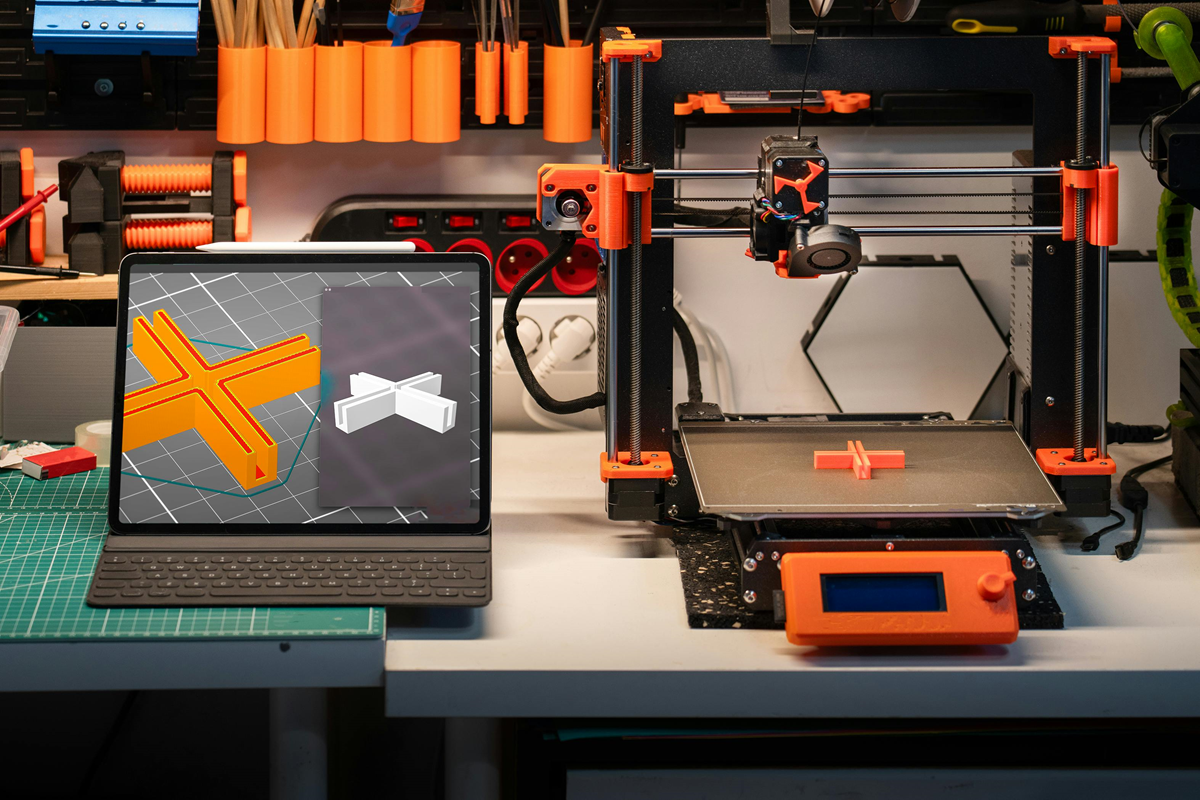

The Silhouette Alta Plus lets you craft away from two dimensions by enabling you to print three-dimensional models. However, in order to get a full ROI on this capability, you need to know what 3D printing materials to use and how they work with Silhouette machines. The material that you choose will affect not only the aesthetic view but also the structural and functional strength of your 3D printable designs.

Components of 3D Printing

| Component | Description | Applications |

| Plastics | The most common material, used for a variety of products. Includes PLA, ABS, and PVA. | Toys, household items, prototypes |

| Metals | Strong and durable, used in processes like DMLS for high-strength applications. | Aerospace parts, medical devices |

| Nylon | Known for its flexibility and strength, commonly used in SLS printing. | Functional prototypes, mechanical parts |

| Composites | Materials like carbon fiber enhance strength and reduce weight. | Aerospace components, automotive parts |

| Resins | Used in SLA printing, offering high detail and smooth finishes. | Jewelry, dental applications |

Importance of 3D Printing Software

The Silhouette Alta Plus offers free 3D printing software. It is easy to use and perfect for your 3D printing needs. You can import existing designs, create new models, and easily manipulate them all. Accessing your Silhouette library is fun! You can turn great 2D designs into 3D ones.

Popular Choices for 3D Printing with Silhouette Machine

Here’s a list of various 3D designs printing materials for silhouette machines, along with their unique features and industrial applications:

PLA (polylactic acid)

3D printing experts choose APL as their go-to material. It meets basic user needs and is also eco-friendly. APL comes from cornstarch and sugar cane. This helps it biodegrade when the conditions are right. As a result, APL lasts longer than regular plastics.

Features:

- Easy to use: New users should choose PLA. It is easy to handle because of its low printing temperature. Also, it has minimal shape distortion.

- Solid and strong: PLA is solid and strong, making it great for models and prototypes that need little exposure.

- Biodegradable: Natural resources can create PLA plastics. These plastics break down in industrial composting facilities.

- No smell: Printing with PLA plastic does not trigger any odors to form.

Application:

- Conceptual model: Conceptual models need this model. It makes clear visuals of initial ideas.

- Looks like a prototype: The prototype fits the model perfectly. This creates a look similar to the final product.

- Detailed decoration: Ideal for detailed decorative objects due to its high-resolution possibilities.

ABS (Acrylonitrile Butadiene Styrol)

ABS is a top choice for 3D materials. It is known for its excellent durability and heat resistance. The oil-based plastic is more potent than APL. It also works well for product development and has no special employment restrictions.

Features:

- Durable: It resists impact and wears down slowly. So, it’s great for making parts that must handle different stresses.

- Heat-resistant: This material stays stable above the glass transition of PLA. Its glass temperature helps it keep its structure at higher temperatures.

- Versatile: This material functions across multiple applications that use trusted properties.

Application:

- Functional prototype: The functional prototype is ideal for creating prototypes that work just like the final version.

- Mechanical Parts: Suitable for gears, housings, and other mechanical components.

- Automotive Parts: These are used in cars for both inside and outside parts. They help with thermal and impact stability.

PETG (Polyethylene Terephthalate Glycol)

The modified type of glycol PET glycol (polyethylene terephthalate) is known as PETG. It brings together the better features of both of these two plastics. It is also safe food and easy to print. Also, it’s sustainable, which makes it for a lot of uses.

Features:

- Easy to print: PETG is more straightforward to print than abdominal muscles. It also has less distortion and layer adhesion.

- Moisture and chemical resistant: PETG is somewhat moisture resistant and chemically resistant. Thus, it is well suited for the harsh environment.

- High transparency: PETG has excellent transparency. It can create parts that are either fully clear or semi-clear, making it great for transparent structures.

- Food safe: Some of the PETG filaments are food safe. This will make them suitable for containers and cooking tools.

Applications:

- Waterproof applications: This type works well for containers, bottles, and more to keep out liquids.

- Snap-fit components: Adapted to parts that will not work together correctly if they are not ‘held together’ or are not ‘fixed.’

- Protective cases: It is a protection case and an eco-friendly case for electronics and other delicate items.

TPU (Thermoplastic Polyurethane)

TPU is a very flexible and elastic material that allows you to print flexion and bending. It has unique qualities that make it a top choice for uses needing shock absorption and flexibility.

Features:

- Flexible and stretch: The TPU can stretch and fold without breaking, and it lends itself well to any flexible detail.

- Impact resistant: TPU absorbs strikes and shields printed parts against damage.

- Vibration demonstration: We give examples of reduction in vibration with the TPU. So, reducing noise is key to making this better for your use.

Applications:

- Flexible prototypes: Perfect for bending or flexing.

- Phone cases: Create protective and shock-absorbent phone cases suitable for phone cases.

- Bracelet, belt, and other portable devices: This is done with the help of Portable Devices.

Specialized materials

Standard materials plus specialized filaments give your 3D prints special properties and a unique look. Composites with wood, metallic plans, and carbon fibers are also included.

- Wood-injected PLA:

- Characteristics: It has a wood look and a wood texture from its wood fibers.

- Applications: Decorative items, architectural models, art projects.

- Metal plain:

- Properties: Looks like a metal, the surface of which contains metal particles (a shiny metal finish).

- Application: Jewelry, decorative accents, costumes.

- Carbon fiber composite material:

- Reinforced with carbon fiber, it gives high strength and rigidity.

- Applications: Functional prototypes, tools, and structural components.

Tips for Choosing an Appropriate Material

To achieve your project goals, it is essential to choose the right 3D printing equipment. Some of the crucial points regarding the selection process are as follows:

Consider the Application

First, the primary use of a 3D-printed object is to be chosen, then comes the choice of material. Is it a mechanical part, a functional prototype, or a decorative object? Requirements vary by application, but 3D printable designs concepts often focus on appearance. However, functional parts should be firm and sustainable.

Evaluate Mechanical Properties

It was assessed for the necessary mechanical properties: resistance, flexibility, and heat resistance. Properties come in different ways. But PLA is easy to use and isn’t all that great at high temperatures. However, ABS is a more durable plastic. Thus, knowing these properties helps you select the suitable material for your project.

Check Printer Compatibility

Check if your Silhouette machine can work with the selected material. Different threads have different parameters and printing conditions are required. Refer to printer specifications and data compatibility. This step is essential to avoid wasting the printer’s resources and the printing obstacles.

Read the Critics

By combining materials and printers, it is possible to find other user experiences. There are useful reviews of materials from online forums that describe how to work with different printers. When considering experience, this information helps in making smart choices.

Experiment

Finally, don’t miss the chance to try different ingredients. See which one fits your needs or preferences best. New ideas can be awakened from different 3D concepts. Additionally, it will help improve overall 3D printing skills. Using good 3D printing software makes it simple to adjust designs and settings. This helps you achieve the best results.

Improvements to 3D Printing Projects

Let me begin with this advice to increase the outcome of 3D work using a silhouette machine:

- Calibrate your printer: Regularly calibrate your Alta® and Silhouette for accurate, consistent prints.

- Keep your filament safe: Store it in a dry, airtight container. This helps prevent humidity absorption. Also, support the wire. This can cause printing problems.

- Use a cooling fan: In the case of PLA printing, use a USB cooling fan to improve the cooling of the printed layer.

- Experimenting settings: Enjoy the trial and error of different settings for 3D designs. This will help you improve print quality.

- Online communities: We are one of the online 3D printing communities. Consistently learn new ways of solving problems and methods, and help each other.

Conclusion

The key to deciding the right material for 3D printing is using a silhouette machine. It facilitates making high-quality, detailed, and strong 3D designs. Use APL for a sleek design. Use ABS for strong durability. Use PETG for a neutral look. Lastly, use TPU for flexibility. However, it helps to understand each material’s traits and how to use it creatively. It’s helpful. You can use professional materials with PLAs in wood and metal projects to stand out. It helps you create impressive 3D-printed parts. With the right material and silhouette machine, your imagination is limitless.