Statistically, aluminum C channels are the favourite choices in different industries. But what’s behind the fame? Well, the C channels are versatile and durable, but above all, they have a distinct C shape profile.

That means better support, reinforcement, and aesthetic appeal, which are vital for different uses. Considering the strength-to-weight ratio and the ability to triumph over rust, they seamlessly take their position in the architecture, manufacturing, aerospace, and automotive sectors.

Yet the big question is, are there types of aluminum C channels? Let’s find out, shall we?

The standard aluminum C channel

Though essential, the standard C channel is the primarily used aluminum C channel. Thanks to the symmetrical C shape design and even flanges on the sides, you may quickly identify it. Its composition guarantees stability and load-bearing capabilities. Even so, that may depend on the various sizes and thicknesses available.

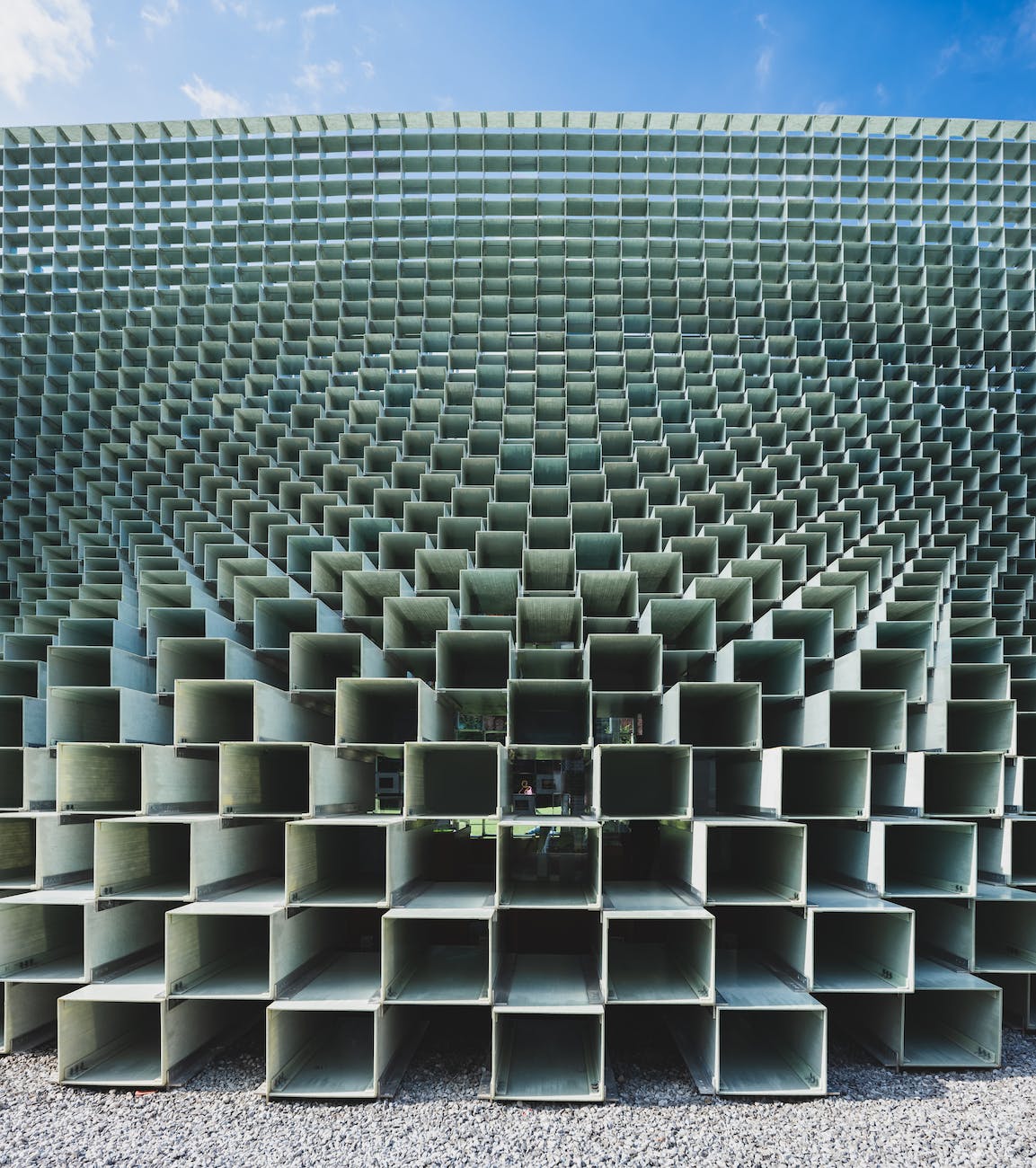

Architectural C channel

Architectural C channel aluminum is one of the aesthetic effects. It has a visually appealing streamlined appearance. But the construction aluminum profile is somewhat slim with round edges, which gives a refined modern appearance. Architectural C channel aluminum is popular with building facades, furniture, and interior design.

Slotted C channel aluminum

The C-channel aluminum with slots is versatile for mounting and hooking up brackets, hangers, and cable units. The channels have specially placed slits along their flange’s length for easy installation and adjustments. The C-slotted aluminum channels are primarily used in electronics and telecommunication industries.

Heavy-duty aluminum C channel

You already know some applications need to support tons of capacity. In that regard, heavy-duty aluminum C channels offer solutions. They are built with thick walls and flanges for more stability. These C channels are used in industrial machinery and material handling units.

Multifunctional aluminum C channels

While you may have different needs, multifunctional aluminum C channels, produced by aluminum presses, may save your day. They combine features of different C channel types to guarantee adaptability. As such, they may have slotted channels, heavy-duty aspects, and slots that offer comprehensive solutions.

Formation and finishes on C-channel aluminum

So, there are different types of C channels. Yet they vary depending on the alloy used. Other alloys have their strengths and resistance to rust. Not to mention, they come with different thermal properties. Long story short, the C channels may use the 6061, 6063, and 3003 alloy profiles.

Then coming on finishes, the C channels may be anodized, powder coated, or retain their natural finish from milling. Anodizing improves resistance against rust and abrasion. But powder coating may give it a spectrum of colours and improve its durability. And when aesthetics is not a concern, the natural mill finish may do the job.

Conclusion

Aluminum C channels are designed for different industrial needs, so it is best to determine what you will use them before heading to the manufacturer. The durability, structural integrity, and quality may differ depending on the manufacturer. That is why you are advised to work with Guangdong Weiye Group as a buyer. After all, they have been in the aluminum industry for more than 30 years.