Table of Contents

- The Growing Demand for Precision in Aerospace

- Critical Role of Fasteners in Aircraft Assembly

- Types of Fasteners Used in Aerospace

- Significant Challenges Facing Fastener Manufacturers

- Innovations Supporting Aerospace Safety

- Impact of Standards and Certification

- Future Perspectives on Aerospace Fastening Solutions

- Conclusion: Building the Future, One Fastener at a Time

The Growing Demand for Precision in Aerospace

Modern aerospace technology is moving forward at an unprecedented pace, setting new benchmarks for performance and dependability across every part of an aircraft. While fasteners may seem inconspicuous, they are foundational to the structural soundness of all types of aerospace vehicles. Manufacturers and maintenance teams increasingly look to top fastener distributors who can provide the stringent quality and precision demanded for today’s cutting-edge aerospace applications.

A significant factor driving innovation in fastener engineering is the industry’s shift towards lighter, stronger materials—a necessity as new technologies and passenger demands propel the expansion of global air travel. According to Reuters’s recently published industry analysis, the struggle to minimize weight while maximizing durability has never been more critical. This focus on excellence puts high-performing fasteners squarely at the center of aerospace manufacturing and safety strategies.

Critical Role of Fasteners in Aircraft Assembly

Every airplane, whether it is designed for carrying cargo, passengers, or military equipment, is constructed using tens of thousands of intricately engineered fasteners. These components connect structural elements and contribute to the safe function of panels, control surfaces, and interior assemblies. A single compromised fastener has the potential to undermine an entire system, which is why quality control processes and frequent inspections are vital during both construction and ongoing fleet maintenance.

Given the high stakes involved, aerospace manufacturers invest considerably in training technicians and developing inspection technologies that ensure each fastener contributes to the overall resilience of the airframe. Failures are rare partly because of the relentless focus on sourcing only the best products from leading suppliers and adhering to proven assembly methods.

Types of Fasteners Used in Aerospace

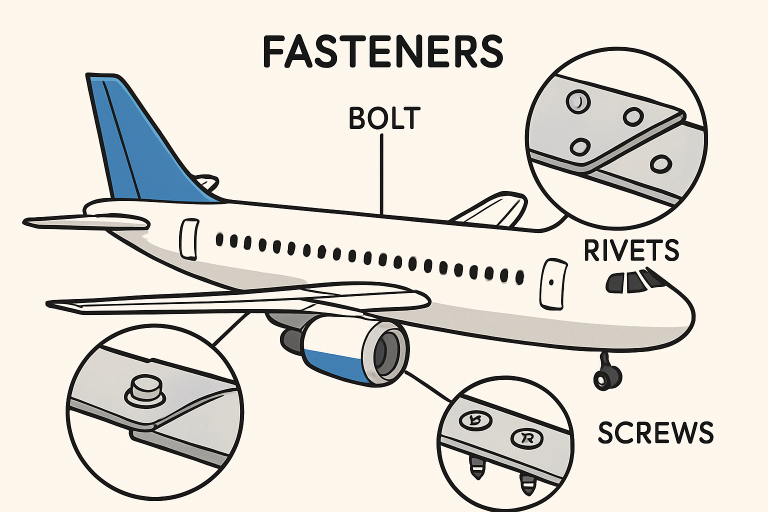

Aerospace applications call for a diverse array of fasteners, each meticulously selected to perform under unique operational stresses and extreme environments. The main categories include:

- Bolts and Screws: These versatile fasteners join major structural assemblies where heavy loads are standard.

- Rivets: Often used to create permanent, reliable joints in fuselage skins and panels, ensuring a flush fit for aerodynamic efficiency.

- Lockbolts: Valued for their robust vibration resistance, vital in dynamic sections such as wings and landing gear assemblies.

- Specialty Fasteners: Engineered for hostile scenarios such as extreme temperatures or high-pressure environments, specialty fasteners include material and design innovations like titanium and composite components.

The location, anticipated load stresses, environmental exposure, and compatibility with modern composite materials drive the selection of the correct fastener. Increasingly, aerospace designers turn to advanced alloys and engineered plastics for challenging applications, further expanding the range of available fastening solutions.

Significant Challenges Facing Fastener Manufacturers

The aerospace industry sets the gold standard regarding quality expectations—even the most minor manufacturing variation can have serious ramifications. Fastener manufacturers must manage:

- Extensive quality control and ongoing compliance audits to ensure every batch meets or exceeds safety regulations.

- Restricted material choices, since only select alloys and coatings are approved for flight-critical applications.

- Pressure to innovate with new production techniques such as additive manufacturing and advanced forging, helping to cut weight while boosting strength and reliability.

According to SAE International, advancements in joining technology are providing both manufacturers and engineers with new approaches to assembling airframes. This reduces the fasteners required in some designs and further improves safety margins.

Innovations Supporting Aerospace Safety

Safety is the bedrock of aerospace engineering, and continuous improvement is non-negotiable. Innovations in fastener technology span advanced corrosion-resistant coatings to self-locking features and improved fatigue performance. Developing and integrating “smart” fasteners—devices equipped with embedded sensors to track tension, load, or vibrational wear in real time—promises a future where potential issues are detected long before they develop into hazards.

These innovations enhance flight safety and contribute to reduced maintenance costs and improved fleet management, which is a win for both operators and travelers. Forbes reports that such advances are already leading to greater confidence in today’s high-performance aircraft.

Impact of Standards and Certification

The aerospace sector is rigorously regulated, with international organizations like SAE International setting consistent benchmarks for chemical composition, mechanical attributes, and dimensional accuracy. Certification processes improve traceability and guarantee a part’s suitability for its intended application. For component suppliers, achieving and maintaining required certifications demonstrates commitment to excellence—strengthening their position as trusted partners to the world’s aircraft manufacturers.

This strict adherence to global standards reduces the risk of service failures. For operators, rigorous documentation is essential, streamlining investigations and maximizing transparency throughout a component’s life cycle.

Future Perspectives on Aerospace Fastening Solutions

The aerospace field constantly looks ahead, marrying new materials, manufacturing techniques, and monitoring systems to create next-generation airframes. Trends to watch include nanomaterials, lightweight composite fasteners, and automated assembly lines leveraging robotics and artificial intelligence. Such transformations will redefine reliability and efficiency, enabling breakthroughs in everything from hypersonic flight to reusable space vehicles.

Scientists and engineers continue to research and test joining solutions that push the boundaries of current possibilities. In the coming decades, these innovations will support more ambitious missions—both in the skies and beyond the atmosphere.

Conclusion: Building the Future, One Fastener at a Time

Precision fasteners remain unsung heroes at the heart of aerospace innovation. As advanced technologies emerge and flight grows more complex, the evolution of aerospace fasteners will ensure structures remain safe, efficient, and resilient. Modern aircraft depend on the perfect union of materials and the dedicated expertise of those who design, manufacture, and maintain these vital components. The next generation of aerospace technology will be built—quite literally—one fastener at a time.