How do I choose the best beer dispenser for my bar?

Choosing the right beer dispenser feels overwhelming, but the most critical decision has likely already been made by your bar’s physical layout. Forget the technical jargon for a moment; it all comes down to answering one simple question: Where will you store your kegs? This single factor determines whether you need a simple, self-contained unit or a more complex, remote setup, directly impacting your budget, workflow, and the quality of every pint you pour.

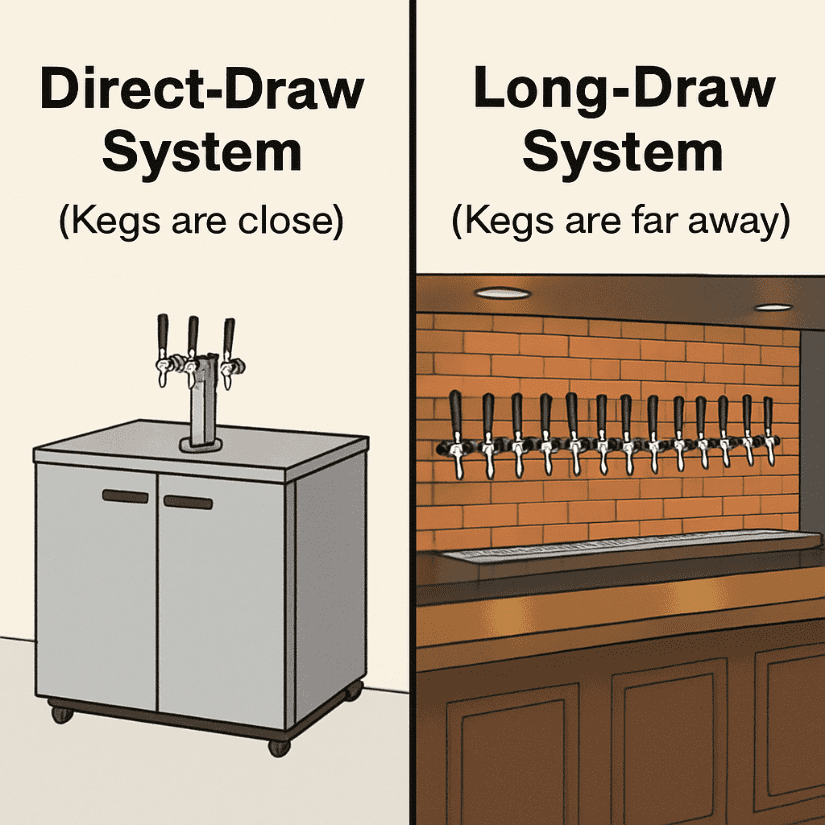

If your kegs will be stored directly under or immediately behind the bar, you’re on the path to a Direct-Draw System. Think of a commercial kegerator—it’s a straightforward, all-in-one solution for keeping beer cold over very short distances. However, if your plans involve a walk-in cooler in the basement or down the hall, you have a distance problem to solve. This requires a Long-Draw (or Remote) System, a more sophisticated setup designed to deliver ice-cold beer from far away without sacrificing quality.

As the image shows, the difference in bar layout planning is stark. A Direct-Draw system keeps everything compact, while a Long-Draw system allows for a sleek bar front with the cold storage hidden elsewhere. Understanding which path your venue requires is the first and most important step toward building a profitable draft beer program. Here is a breakdown of the costs, components, and considerations for each.

Quick overview: the essentials at a glance

- Types: kegerator (direct-draw), remote-draw towers, jockey boxes, and countertop dispensers.

- Capacity: match keg volume to peak demand — ½-barrels for high volume, 1/6 or 1/4 barrels for variety or low-volume lines.

- Cooling & refrigeration: look for consistent cabinet temps (33–38°F for most lagers), quality compressors, and appropriate refrigerant.

- Dispense components: towers, faucets, beer lines, CO₂ regulators, couplers, and drip trays matter as much as the cabinet.

- Serviceability: ease of access, replacement parts, and local service for compressors & refrigeration.

1. Decide which type of beer dispenser fits your bar

A. Built-in / Through-the-counter kegerators (direct-draw)

These are integrated under the bar with a refrigerated cabinet that houses kegs and a tower on the bar top. They’re the industry standard for most bars because they combine storage and dispensing in one unit and deliver short, cold beer lines—reducing foam and preserving flavor. Many commercial models include multiple keg capacities and multiple tap towers for serving several beers simultaneously. Examples of heavy-duty direct-draw units built for bars can be found on HorecaStore (True and ChillCore models are common choices).

B. Remote-draw systems

Remote-draw systems locate the refrigeration unit (walk-in or remote keg box) away from the tap tower and run insulated lines to the bar. This is ideal for long bars, venues with space constraints at the bar, or when you want a clean, compact bar top. Remote systems scale well for high volume and long runs, but initial installation is more complex and requires careful insulation and line balancing.

C. Jockey boxes & portable draft systems

Great for events, patio service, or pop-ups. A jockey box chills beer as it passes through coiled beer lines over ice or through a refrigerated plate chiller. They’re portable and inexpensive versus installing permanent lines, but not ideal as a full-time bar solution.

D. Countertop & residential kegerators

These have smaller capacities and are generally meant for low-volume use or as a backup. Avoid for busy bars except in supplemental / novelty roles.

The Business Case for Direct-Draw: Simple, Affordable, But Space-Hungry

From a business perspective, the primary appeal of a direct-draw system is its cost-effectiveness. As this commercial beer tap system guide shows, because it requires fewer specialized components and less complex installation, the initial investment is significantly lower than for other setups. For new bars or those with a tight budget, this straightforward approach is an attractive and reliable starting point for serving draft beer.

However, that simplicity comes with a significant trade-off: space. Every square foot behind your bar is valuable real estate. A direct-draw cooler or a row of kegerators consumes space that could otherwise be used for storing glassware, high-margin spirits, or an extra ice well. You’re essentially trading lower upfront costs for less operational flexibility and storage capacity right where you need it most.

Beyond just physical space, these under-bar coolers introduce two operational hurdles: heat and noise. The compressor units that keep the beer cold vent warm air directly into your bar area, which your HVAC system must then work harder to overcome. They also create a constant hum, which can impact staff comfort during a long shift and detract from the ambiance for customers seated nearby.

So, the decision boils down to a clear set of pros and cons:

Pros: Lower initial investment; simple to install and maintain.

Cons: Takes up valuable bar space; adds heat and noise; limited tap capacity.

If your bar layout is compact and these drawbacks are deal-breakers, or if you plan on having a large number of taps, you’ll need a way to move your kegs far away from the bar. This brings us to the second main path in choosing commercial beverage dispensers: the long-draw system.

How Many Beer Taps Should Your Bar Actually Have?

After deciding on a system, the next temptation is to maximize your tap count. While a wall of 30 taps looks impressive, more isn’t always better for business. The key to profitability and draft beer quality isn’t variety alone, but the speed at which you sell through each keg. Answering the question of how many beer taps a bar should have is a crucial step in your bar planning.

The main reason for this caution is simple: beer is a perishable product. Once a keg is tapped, a two-to-three-week clock starts ticking before its flavor and quality begin to degrade. A slow-moving keg of specialty ale that takes a month to sell isn’t an asset; it’s a liability that leads to stale beer, wasted money, and unhappy customers.

A successful strategy involves balancing consistency with excitement. Dedicate a core group of taps—your “anchors”—to proven best-sellers that you know will sell quickly. Then, use a smaller number of “rotating” taps for seasonal brews and craft experiments. This gives regulars their reliable favorites while still offering something new to try.

For most new bars and restaurants, starting with 8 to 12 taps is a solid, data-driven sweet spot. This count provides enough room for 4-6 high-velocity anchors and 4-6 rotating taps, ensuring everything stays fresh without overwhelming your inventory. Once you’ve chosen your taps, the next step is deciding what will power them in the “engine room” of your system: the gas.

Installation considerations & bar layout

Under-bar clearance: Measure space for a kegerator or refrigeration cabinet and allow service access for compressors.

Tap spacing & tower placement: Position towers to minimize reach for bartenders and to keep lines short.

Drainage & drip trays: Ensure adequate drainage or drain to a floor drain. Many commercial dispensers include integrated drip trays.

Ventilation: Compressors need ventilation; avoid enclosed cupboards without ventilation.

Electrical supply: Verify circuit capacity; heavy compressors may need dedicated circuits.

Cleaning and maintenance: longevity and safety

A consistent cleaning schedule preserves beer quality and prevents off flavors:

- Weekly: Clean faucets and drip trays.

- Every 2 weeks to monthly: Clean beer lines with a food-grade line cleaner (frequency depends on throughput and beer types).

- Every 3–6 months: Replace worn O-rings, check couplers, inspect tower seals and insulation.

- Annual: Service compressor and refrigeration components, replace aging hoses and manifold parts.

Document your cleaning schedule and train bar staff — the cost of neglect is wasted beer and unhappy customers.

Recommended commercial models (available on HorecaStore)

Below are several commercial options you can consider from HorecaStore. Each selection highlights the unit’s best use case so you can match it to your bar’s needs.

- ChillCore Series 24″ Kegerator Beer Dispenser (Dual Tap) — compact, suitable for smaller bars or satellite service counters; holds 1/2 barrel and offers precise digital controls. Great when you need a professional look in a limited space.

- True 23″ Kegerator (1-keg capacity) — American-made, energy efficient, ideal for lower-volume taps or specialty lines (nitro stout or seasonal taps). Known for reliable compressors and a strong warranty.

- True 59″ / 69″ / 92″ Kegerator Beer Dispensers (multi-keg capacity) — these larger units (2- to 4-keg capacity or more) suit high-volume bars and restaurants needing several permanent draft lines. They provide strong temperature control, stainless steel tops, and long warranties — a solid choice for main bar installations.

- Beverage-Air Club Top Kegerator (single/double tap options) — designed for reliable cooling and energy efficiency; good for bars that want a proven commercial brand with low maintenance.

- Everest EBD4-24 / Large Multi-Keg Refrigerators — for very high volume venues needing 3–4+ keg capacity and robust NSF-certified refrigeration. These are ideal where uptime and capacity are mission-critical.

Tip: When comparing models on HorecaStore, pay close attention to stated keg capacities, the number of taps, refrigerant type, available warranties, and lead times for shipping.

Quick maintenance routine (printable)

- Daily: Empty drip trays, inspect towers & faucets.

- Weekly: Clean faucets and couplers, check CO₂ tank pressure.

- Every 2–4 weeks: Clean beer lines with appropriate cleaner.

- Quarterly: Inspect all hoses, O-rings, and manifold seals.

- Annually: Professional refrigeration service — check compressor, refrigerant, and seals.

Final checklist before purchase

Use this checklist to finalize your decision:

- Does the unit have the keg capacity you need for peak service?

- Are the number of taps aligned with your menu?

- Is the refrigeration spec (temp range, compressor) suitable for the beers you’ll serve?

- Is the installation (ventilation, electrical, plumbing) compatible with your bar?

- What are the warranty terms and expected lead time for delivery & service?

- Are replacement parts & consumables readily available?

- Does the dispenser integrate with your cleaning regimen (easy to disassemble/clean)?

Conclusion

Choosing the best beer dispenser for your bar is a balance between capacity, quality of components, refrigeration performance, and long-term serviceability. For most commercial bars, a direct-draw kegerator from an industry brand is the best combination of reliability and serviceability. Larger venues should consider multi-keg units or remote draw systems to handle volume, while pop-ups and events get great flexibility from jockey boxes.