Precision in modern manufacturing defines more than just quality; it also determines competitiveness, repeatability, and customer trust. Demand for accurate techniques grows increasingly evident as businesses move toward smaller tolerances and complex detailing. Not only can laser engraving provide precise, reliable marks, but it also integrates seamlessly into high-volume operations where speed is not sacrificed. The sophistication of this technology has turned a niche operation into a necessary tool for companies that prioritize operational control and clean detail in their manufacturing lines.

The Role of Focused Energy in Creating Impeccable Detail

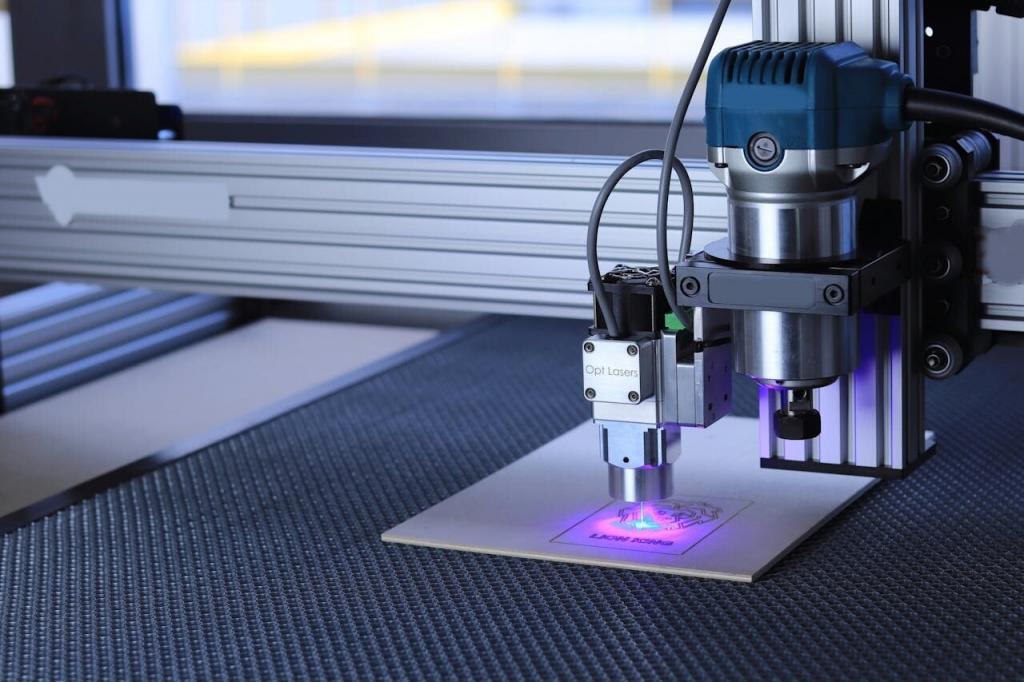

Laser engraving depends on the strong concentration of light energy to interact with the surface of a substance in a highly controlled manner. This technique guarantees exact definition and consistency in every mark, regardless of its complexity or tiny size. Without physical distortion or tool wear, you can apply this control over a broad spectrum of materials, including metal and plastics, as well as ceramics. In industries like aircraft, automotive, or electronics, where part identification and traceability are crucial, that benefit becomes absolutely vital. Even the most complex alphabetic codes, barcodes, or micro-patterns are etched exactly uniformly across hundreds or thousands of units with a carefully calibrated beam.

Material Compatibility Without Compromising on Accuracy

Precision is meaningless if the material type limits it. Fortunately, laser engraving is quite flexible and fits several surfaces. Depending on the material, you can vary wavelengths, power settings, and pulse durations to provide ideal energy delivery, guaranteeing clean results. This versatility in a facility manufacturing mixed-material components—such as a mix of high-performance plastics and stainless steel fittings—allows you to achieve consistent precision over the whole product line without retooling. Laser techniques address everything from anodized metal to carbon composites without destroying underlying structures, unlike mechanical techniques that struggle with surface hardness or coating layers. That adaptability lets your facility maintain constant quality standards even while you are switching between different manufacturing runs.

Automation Integration for Scalable and Repeatable Output

Modern production depends on automation; hence, laser engraving is precisely in line with this system. The process is software-controlled, allowing for real-time changes, seamless data integration, and minimal operator intervention. Once configured, the system runs repetitive tasks batch after batch with the same accuracy. To get unique data per part, such as serial numbers or batch codes, a laser engraver machine set for high-throughput applications integrates readily with conveyor systems, robotics, and central databases. This degree of connectivity ensures not only accuracy but also traceability—an increasingly crucial component in quality control and regulatory compliance. Lack of consumables also lowers waste and downtime, enabling your production plan to remain scalable and predictable without regular interruption of maintenance.

Consistent Performance Even on Microscopic Features

Small does not mean simple—especially when designating micro-components for the medical, electronics, or instrumentation domains. These sectors need legibility under magnification IDs without compromising structural integrity. Laser engraving accomplishes exactly that. Precise marks created by focused beams with micron-level precision ensure visibility on small surfaces and thereby guarantee quality control at the smallest possible scale. Whether it’s coding a medical implant, identifying a printed circuit board, or serializing a tiny sensor housing, the ability to engrave without vibration or too much heat transfer preserves the integrity of even the most delicate parts. This capacity lets your operation expand into advanced manufacturing sectors without altering your process flow and handle industries with rigorous certification criteria.

Reduced Waste and Environmental Impact Through Clean Processing

Engraving precision is only one aspect of the process. Just as much depends on clean production, particularly as businesses strive toward environmental stewardship and sustainability. In contrast to ink printing or chemical etching, laser engraving doesn’t use any disposable materials, solvents, or emissions. There are no abrasives, no inks, and no additional cleanup since the process is inherently contactless and non-invasive. This method not only ensures worker safety but also reduces the production of scrap and hazards of contamination. Lean manufacturing goals are supported by every etched item coming out ready for use without further handling.

Conclusion

High accuracy is the outcome of intentional decisions in technology, process control, and adaptability; it cannot be obtained by accident. More than merely fine detail, laser engraving adds repeatability, adaptability, and integration into rigorous processes where exactness cannot be sacrificed. This approach is a consistent force of accuracy when your facility must supply consistent quality throughout a range of materials, scales, and production speeds. From mass production to micro-detailing, the results speak with the sharp clarity that only laser technology can provide, etching your commitment to quality directly into each product.