Table of Contents

- Understanding Load Capacity

- Assessing Floor Conditions

- Choosing Wheel Materials

- Selecting Wheel Diameter

- Deciding Between Fixed and Swivel Casters

- Considering Brakes and Locks

- Evaluating Environmental Factors

- Avoiding Common Mistakes

Selecting the right casters is essential to maintaining equipment safety, ensuring smooth mobility, and preventing unnecessary damage to flooring or injury to staff. With numerous types of casters and wheels available, selecting the best option for your specific environment requires careful evaluation. High-quality components, such as stainless steel roller bearings, play a crucial role in overall performance and longevity, making them a popular choice for industries that prioritize durability and smooth operation.

As equipment load, mobility needs, and operational context vary widely from one setting to another, understanding what to look for in caster selection makes all the difference. This comprehensive guide covers the most important considerations for choosing casters that support efficiency, safety, and long-term value.

Understanding Load Capacity

The caster’s load capacity determines how much weight it can safely handle. To find your minimum capacity requirement, divide the combined weight of the equipment and its maximum load by the number of casters on the unit. Always add a safety margin—industry experts recommend selecting casters rated 25–30% higher than your calculated need to accommodate uneven loads or shifting weights. For instance, a 400-pound cart with four casters requires each caster to be rated for at least 100 pounds, but ideally, look for 125–130 pounds per caster.

Assessing Floor Conditions

Flooring material and surface irregularities directly influence caster and wheel choice. Hard, smooth surfaces like tile benefit from softer wheels such as rubber or polyurethane, which cushion movement and protect the floor finish. On the other hand, harder wheels made of nylon or hard polyurethane roll more easily on carpets, resisting the friction and snagging that softer wheels may encounter. Oversized wheels may be necessary for surfaces with cracks, thresholds, or debris, allowing the equipment to roll smoothly and safely across obstacles.

Choosing Wheel Materials

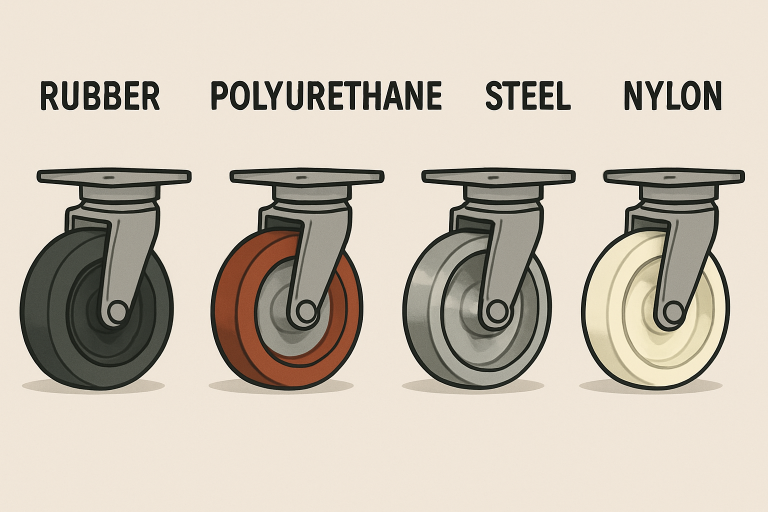

The right wheel material affects mobility, lifespan, and even floor protection. Typical options include:

- Rubber: Excellent for shock absorption and quiet movement. Best for indoor, hard-surface flooring.

- Polyurethane: Offers superior resilience, supports higher loads, and resists oils and chemicals. Safe for a variety of floor types.

- Steel or Cast Iron: Ideal for tough, industrial floors and the heaviest loads, but may cause damage if used on delicate surfaces.

- Nylon or Plastic: Lightweight, corrosion-resistant, and effective for wet or food-service environments.

Ensure your wheel material not only matches the surface needs but also resists environmental threats such as moisture, chemicals, or abrasion.

Selecting Wheel Diameter

Wheel diameter plays a major role in performance. Larger wheels traverse uneven floors, gaps, or thresholds more effectively, requiring less effort to start and maintain movement. They also distribute weight more broadly, reducing flooring wear and enhancing maneuverability. However, balance your choice with the physical constraints of your equipment and work environment to avoid clearance issues or interference with equipment design.

Deciding Between Fixed and Swivel Casters

To select caster types, consider your mobility needs. Fixed casters provide straight-line tracking, making them suitable for heavy loads, while swivel casters can rotate 360°, offering multidirectional movement and improved maneuverability. A combination of two fixed and two swivel casters generally optimizes steering and stability. In confined areas or when frequent direction changes are necessary, using all-swivel casters enhances flexibility.

Considering Brakes and Locks

Brakes and locking mechanisms are essential for ensuring safety and control in operations, particularly when equipment is stationary. The primary braking options include wheel brakes, which stop the wheel’s rotation to prevent movement, and total-lock brakes, which secure both the wheel and the swivel bearing to stop all movement and rotation. The selection of braking systems should align with safety protocols and the specific tasks at hand, with total-lock brakes being particularly vital for medical carts and platforms in critical environments.

Evaluating Environmental Factors

Successful caster selection is influenced by various environmental factors. Temperature extremes can damage certain wheel materials; however, stainless steel and specialized coatings are recommended for withstanding exposure to moisture and chemicals during washdowns. In noise-sensitive environments, employing casters designed for quieter operation is crucial. It is essential to match caster materials to specific conditions to ensure both durability and safety.

Avoiding Common Mistakes

Many users often encounter avoidable mistakes in caster selection, such as overloading beyond capacity, mismatching wheel materials leading to floor damage, and neglecting maintenance, which can decrease lifespan and compromise safety. Regular maintenance and the correct matching of caster properties to specific needs can help mitigate these issues. Understanding requirements—like load, floor types, mobility needs, and environmental conditions—ensures safer and more efficient caster choices.

Conclusion

Choosing suitable casters involves balancing load capacity, floor conditions, wheel materials, mobility needs, and environmental factors. Calculating weight, selecting appropriate wheels, and choosing the right caster types and brakes improve safety and efficiency. Avoiding common mistakes like underestimating load demands or neglecting maintenance extends caster life and protects floors and equipment. Properly aligned, casters support better maneuverability, reduce risks, and enable smoother movement.