Poor design decisions are rarely just aesthetic missteps. They often carry hidden costs that ripple across engineering, procurement, production, quality, and customer service. When products are designed without manufacturability in mind, teams face late-stage rework, unstable supply chains, inflated scrap rates, and frustrating launch delays. The remedy is design for manufacturability, a disciplined approach that integrates production realities early in concept development. By aligning geometry, materials, tolerances, and assembly strategies with the capabilities of your processes and suppliers, you can curb waste, protect margins, and accelerate time to market. The payoff is not only measured in efficiency but also in reliability, scalability, and customer satisfaction.

The Real Price of Design-Induced Waste

Bad design multiplies cost in ways that do not show up until late in the product lifecycle. Complex geometries can require specialized tooling and multi-step operations that inflate setup time and per-part cost. Tight, nonfunctional tolerances drive unnecessary inspection overhead and increase the likelihood of nonconformances. Exotic materials may offer theoretical performance improvements but introduce procurement risk and longer lead times, especially when only a handful of suppliers can process them. When design overlooks standard hole sizes, bend radii, thread specifications, and stock thicknesses, the result is custom fixtures, off-cycle adjustments, and extended changeovers that slow flow on the shop floor.

There is also the cumulative impact of rework. Even minor redesigns trigger ECOs, requalification efforts, PPAP updates, new tool paths, and adjusted control plans. These changes drain engineering bandwidth and can stall production at critical moments. Quality costs rise through higher scrap and more frequent deviation approvals. Warranty risk grows when designs rely on process miracles rather than robust specifications. What looks like a small deviation in CAD can become a cascade of operational disruptions that swell total landed cost.

Designing With Process Constraints in Mind

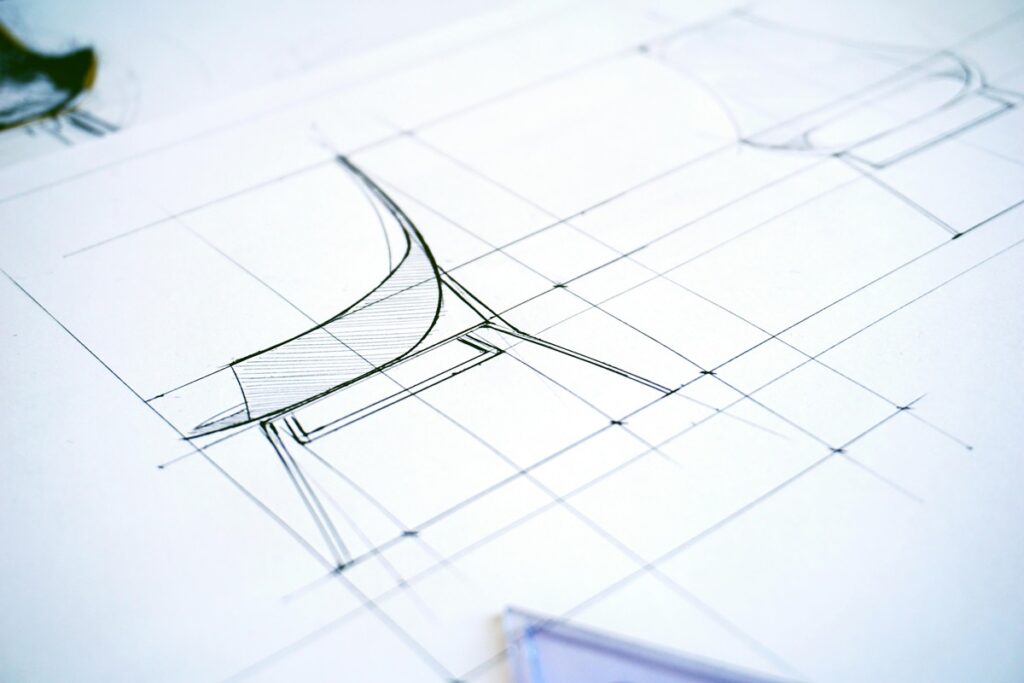

Mastering manufacturability starts with understanding the constraints and capabilities of the processes that will build your product. Sheet metal bending has natural limits on minimum flange lengths and hem radii based on tool geometry. Injection molding dictates uniform wall thickness and draft to ensure smooth ejection and avoid sink marks. Machining favors simplified features, adequate tool access, and tolerances matched to machine precision. Additive manufacturing can unlock complex internal structures but still requires consideration for support removal, surface finish, and post-processing.

A practical approach is to codify process rules as design standards and incorporate them into CAD templates, parametric features, and libraries. Encourage early collaboration between design engineering, manufacturing engineering, and supplier technical teams. Host buildability reviews at concept freeze to test feasibility and identify risk. Align tolerance stacks with measurement capability and define critical to quality features with specific control plans. Use DFMEA to anticipate failure modes tied to production variability, then mitigate through geometry choices and clear specifications. When design choices are anchored in process truth, prototypes validate faster and production ramps smoother.

Material Choices and Their Downstream Effects

Materials drive manufacturability as much as geometry. Selecting alloys, plastics, coatings, and adhesives should be guided by both functional performance and production practicality. Availability matters. Standard grades are easier to source at scale and typically come with better quality consistency and shorter lead times. Formability affects yields in bending and stamping. Heat treatability influences distortion risk and dimensional stability. Surface finish requirements must be compatible with downstream processes such as painting, plating, or welding.

Consider the total system. A harder material might reduce wear in service but could dramatically increase tool wear and slow cycle times. A high-temperature plastic may meet an environmental spec but require longer cooling, raising part cost and capacity needs. Coating choices can complicate grounding, conductivity, or bonding. Align material specifications with supplier process windows to avoid fighting physics. Where possible, validate alternates that offer similar performance with friendlier processing characteristics. Document rationales so procurement and quality teams understand the intent and do not inadvertently approve substitutes that compromise downstream operations.

Tolerances, GD&T, and the Cost of Precision

Precision is expensive when it is not essential. A common source of hidden cost is over-tolerancing features that are not functionally critical. Every micron of precision narrows the process window and increases setup time, inspection frequency, and scrap risk. Geometric dimensioning and tolerancing (GD&T) is powerful when used to control what truly matters, like perpendicularity on mating surfaces or position on hole patterns that affect assembly alignment. It becomes costly when applied indiscriminately to non-critical features.

To manage this, establish clear functional requirements for each feature and trace them to measurable characteristics. Build tolerance stacks to show where tight control is needed and where process capability is already sufficient. Match tolerances to measurement methods that are repeatable and practical on the shop floor. Where fit is driven by assembly, use fixtures or self-locating features to reduce sensitivity to variation. Standardize datum schemes to avoid ambiguity. The goal is robust products that assemble and perform as designed without imposing unnecessary burden on manufacturing.

Supplier Collaboration and Early Engagement

Suppliers are partners in manufacturability. They hold the tribal knowledge of what runs smoothly and what causes headaches. Bring them in early, especially on parts that rely on specialized forming, cutting, or molding. A trusted metal stamping manufacturer can advise on die design, feature placement, burr direction, and coil width optimization that lowers material waste and improves throughput. Likewise, molders can flag thick sections, inadequate draft, or gate locations that limit process control. Machinists will caution against deep, narrow pockets or unreachable fillets that require custom tooling.

Formalize this collaboration through technical reviews, pre-production builds, and capability studies. Share design intent, load cases, and functional priorities so suppliers can propose alternatives that achieve the same outcomes with better manufacturability. Use sample parts and pilot runs to validate assumptions before committing capital to tooling. Contract for clear quality requirements that reflect process realities instead of aspirational tolerances. When supplier expertise shapes the design early, you prevent late-stage surprises and establish a foundation for stable, scalable production.

Building a Culture of Manufacturability

Process-aware design cannot be a one-off initiative. It needs to become a habit supported by tools, governance, and metrics. Create checklists that cover process rules, material availability, tolerance rationale, assembly strategy, and inspection planning. Integrate manufacturability scoring into design reviews and make it a gate for release. Capture lessons learned in a common repository with photos, defect data, and corrective actions so teams do not repeat mistakes. Train engineers on production processes and rotate them through the shop floor to build empathy for operators and testers.

Measure what matters. Track ECO counts after design freeze, first-pass yield, scrap rates by feature category, and supplier change requests. Correlate these metrics to design decisions so teams see the impact. Reward designs that hit performance goals while minimizing production friction. Encourage simplicity where possible. Simpler parts typically cost less, assemble faster, and fail less. When manufacturability is embedded in the culture, product development becomes more predictable and launches become less stressful.

Conclusion

The hidden cost of bad design is paid in delays, waste, and customer dissatisfaction. By mastering manufacturability, product teams convert production constraints into design advantages. Align geometry with process capabilities, choose materials that balance performance and practicality, control only the tolerances that matter, and involve suppliers early. Build a culture that treats manufacturability as a first-class requirement alongside function and aesthetics. The result is faster launches, healthier margins, and products that serve customers reliably at scale.