Table of Contents

- Laser-Hybrid Welding

- Friction Stir Welding

- Electron Beam Welding

- Ultrasonic Welding

- Augmented Reality in Welding

- Automation and Robotics

- Sustainable Welding Practices

- Additive Manufacturing Integration

Welding is at the forefront of modern manufacturing, constantly evolving with the latest technological breakthroughs. Today, industries ranging from automotive to shipbuilding rely on advanced welding processes that improve precision, lower costs, and increase the versatility of materials that can be joined. By adopting innovations such as friction stir welding or integrating robotics, businesses like any leading welding manufacturer in South Carolina are able to boost efficiency, safety, and product quality.

Staying informed about these technologies is essential for remaining competitive in global markets. Embracing cutting-edge approaches enables organizations to minimize defects, conserve resources, and capitalize on new opportunities for design and assembly. This comprehensive guide explores the most impactful welding advancements shaping the industry today.

Laser-Hybrid Welding

Laser-hybrid welding seamlessly combines the benefits of laser beam welding and arc welding into a single, powerful process. This method utilizes the deep-penetration capabilities of lasers, combined with the flexibility and filler material support of arc welding. The result is significantly faster speeds, reduced thermal distortion, and stronger, finer weld seams with a lower risk of common issues such as porosity in welding. Industries such as automotive and shipbuilding utilize laser-hybrid welding to create intricate, high-strength assemblies that would be nearly impossible to achieve with traditional welding alone.

Friction Stir Welding

Friction Stir Welding (FSW) is a solid-state joining process transforming industries where conventional fusion welding falls short. By rotating a specialized tool against the joining materials, FSW generates heat through friction, allowing metals to soften and mix without melting. This produces welds with exceptional mechanical properties and minimal distortion, even for dissimilar metals and thin constructions. FSW’s impact is profound in the aerospace, rail, and automotive sectors, offering new options for lightweight assemblies that combine strength and durability.

Electron Beam Welding

Electron Beam Welding (EBW) is a precision welding technology that employs a focused high-velocity electron stream within a vacuum chamber. The resulting deep, narrow fusion zone minimizes distortion, producing exceptionally clean and strong welds. EBW’s ability to join complex geometries and highly reactive metals makes it indispensable for advanced sectors, especially space and nuclear power industries, where safety and reliability are paramount.

Ultrasonic Welding

Ultrasonic welding uses sound waves at ultrasonic frequencies to bond materials through localized frictional heat. Unlike heat-based welding, this innovative technique joins components without melting them, making it particularly effective for plastics, thin metals, and delicate electronic assemblies. The process is fast, energy-efficient, and capable of joining dissimilar materials, leading to widespread use in medical device and electronics manufacturing.

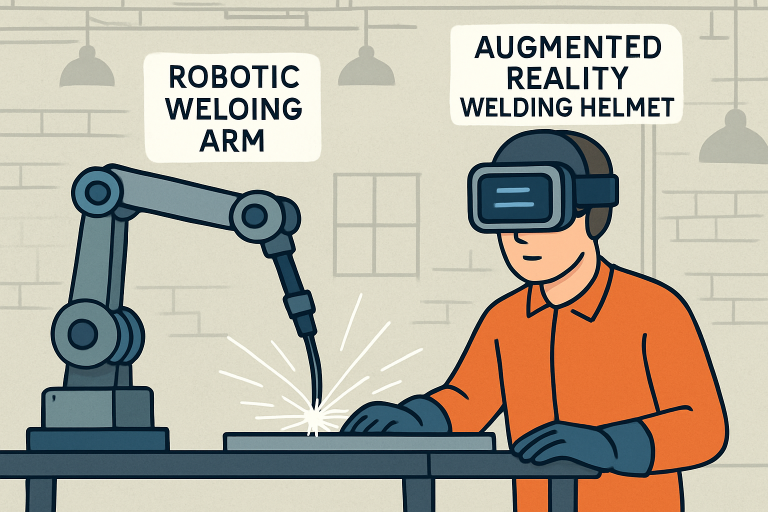

Augmented Reality in Welding

Augmented Reality (AR) is transforming how welders train and perform real-time assembly operations. AR-based welding helmets and systems superimpose detailed guides, safety instructions, and instant performance feedback directly onto the user’s field of vision. This immediate support shortens training time, enhances precision, and significantly reduces the risk of mistakes. AR integration helps shops optimize workflow and maintain consistent, high-quality output.

Automation and Robotics

The automation revolution in welding is driven by robots and collaborative robots (cobots) capable of executing complex, repetitive, or hazardous welds with unwavering accuracy. By automating difficult tasks, factories raise throughput, protect skilled workers from harm, and ensure uniform quality. As outlined by OSHA’s robotics guidelines, these technologies also emphasize safety in robotic welding environments. Modern collaborative robots (cobots) safely share workspace with human operators, allowing for a flexible production environment where machines and people complement each other’s strengths.

Beyond just individual robotic cells, the true power of automation lies in its integration across the entire manufacturing workflow. Companies that excel in this area often combine advanced robotic welding with precision metal stamping and complex assembly lines to deliver comprehensive solutions. This holistic approach ensures consistent quality and efficiency, making them trusted partners for high-volume production. For instance, companies like Spartanburg Steel Products can leverage extensive manufacturing capabilities, including tandem and progressive press lines, alongside robotic welding and automation integration, to manage complex projects from start to finish. Such integrated systems are crucial for meeting the stringent demands of modern industries.

Sustainable Welding Practices

The welding industry is advancing toward a sustainable future by prioritizing energy efficiency and waste reduction. Methods such as Friction Stir Welding and precision laser welding reduce power consumption and material loss. Additionally, companies are promoting the recycling of metals and using environmentally friendly equipment to cut greenhouse gas emissions. Embracing greener technological alternatives not only benefits the environment but also reduces costs and improves overall competitiveness.

Additive Manufacturing Integration

Combining additive manufacturing (3D printing) with advanced welding technologies unlocks a new era of innovation. This synergy enables manufacturers to create highly customized, complex geometries that are otherwise difficult or impossible to achieve through traditional processes. It also accelerates prototyping, reduces material waste, and enables the rapid production of specialized components, particularly in the aerospace and automotive industries. By adopting these advanced welding techniques, organizations not only enhance product quality but also position themselves for sustainable growth and innovation in the ever-changing world of manufacturing and construction.