Metal fabrication is an important industry. To keep up with client demands and modern practices, you can enhance your operation. Check out the best ways to improve your metal shop and implement these suggestions soon!

Update the HVAC System

Extreme temperatures affect metal. For instance, warm temperatures can produce moisture in the shop’s air and lead to rust and corrosion. Not only will moisture hinder material but also damage projects. Regulate shop temperatures by updating the HVAC system. Ensure good ventilation and climate control year-round with a new unit.

Integrate Metal Processing Automation

Improve efficiency and precision with automated metal processing equipment. Automation systems can handle bulky and heavy materials. They can cut, punch, and weld items. For example, they can form shapes for manufacturing square metal tubes or round tubes. The systems reduce operator errors and speed up tasks. It’s great to integrate automated systems to complete projects faster.

Follow Routine Machine and Tool Maintenance

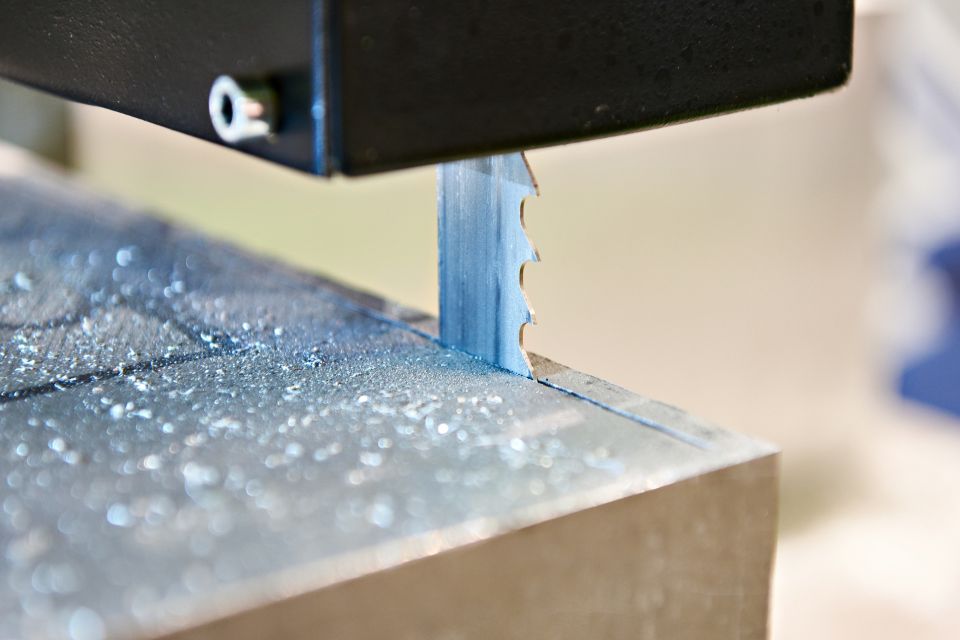

Machine and tool maintenance ensures quality projects with accurate dimensions. Given the reliance on equipment, it’s essential to follow a maintenance routine. This may include replacing the hydraulic fluid, disassembling tools, inspecting machines, and watching out for corrosion. It’s also important to know when it’s time to replace material.

For example, inaccurate cutting is a sign you need a band saw blade replacement. Precision is critical for metal fabrication, and you don’t want to dimmish the quality of work. It’s best to repair or replace equipment rather than ignore problems.

Enhance Client Communication

Enhancing client communication is a smart way to improve your metal shop. After all, what’s a shop without customers? To improve communication, develop a detailed ordering process. Discuss client orders and note special changes. While fabricating their pieces, offer project updates. Send text messages or emails about order completions or shipping dates. You can also discuss possible delays. Ultimately, keeping clients in the loop is always a good idea.

Promote a Safety Culture Among Workers

With heavy machinery and various tools, the shop floor can be a dangerous place. To protect employees and reiterate safety protocols, always promote a safety culture. Lead by example, and wear safety glasses, steel-toe boots, and tie your hair back. Furthermore, provide posters and manuals that address safety topics and best practices. The more you prioritize safety, the more your workers will follow the rules within the workplace.