Safety is a top concern in industrial settings because mishaps may happen due to the most unexpected reasons. If you are a chemical manufacturer, you need to be extra conscious because the industry is inherently high-risk. A leak or spill can have dire implications for the well-being of your workers. The hazards may extend to your assets because inflammable chemicals can cause a fire. Fortunately, a cautious approach is enough to address risks and avoid mishaps. The New Year is the best time to assess your risks and implement relevant safety measures to resolve them. Here are some actionable steps to enhance safety in your chemical plant in 2023.

Organize the premises

Planning and organizing your premises is crucial when dealing with the production and use of hazardous chemicals. Start by assessing the location of raw materials and finished products. Verify that containers are not near other chemicals they may react with. Also, declutter the floor frequently to prevent slip and fall mishaps. Ensure proper ventilation and drainage to address a container breach. Set up exhaust vents to lower the risk of gas leaks.

Label everything

Another simple measure to prevent hazards in your chemical factory is to label all containers clearly. Since chemicals often look alike, your employees may make mistakes while handling, mixing, or disposing of them. But only putting a label on containers can prevent mishaps. You can go the extra mile by adding potential hazards, handling instructions, and precautions to the labels. Additionally, if your factory deals with waste disposal, it’s essential to partner with a professional waste management service to properly get rid of hazardous waste.

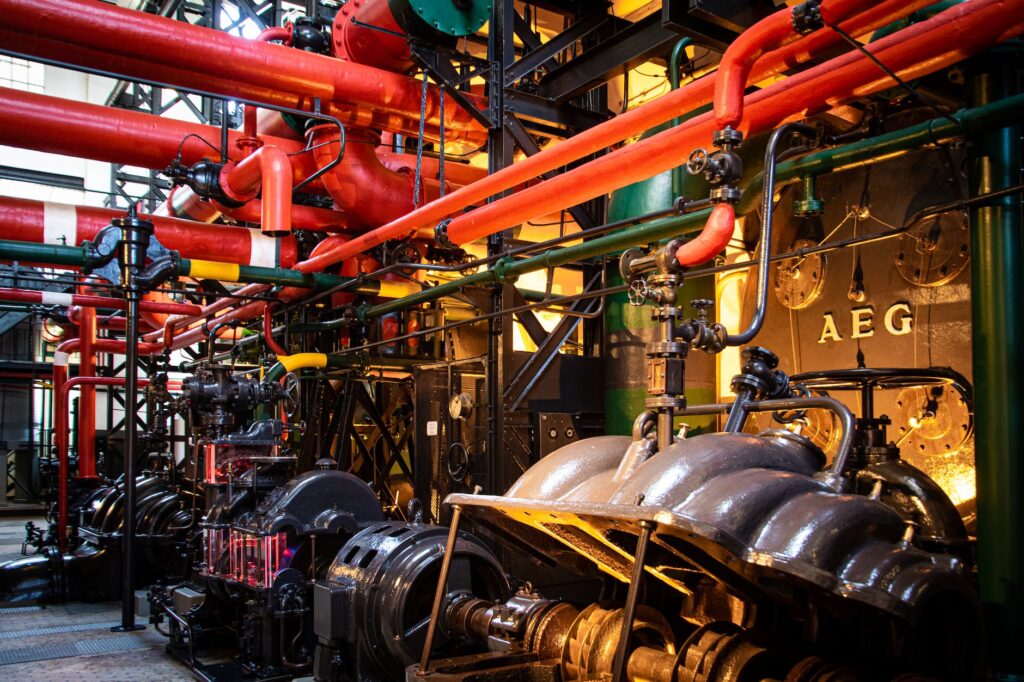

Invest in top-grade equipment

Industrial operations in the chemical sector include the storage and transfer of substances. Both can be dangerous if you do not have the right equipment in place. For example, storage reservoirs should not be made of corrosive materials. Similarly, you must invest in top-grade magnetic pumps to ensure safety when transferring chemicals during the production process. Assess your equipment this New Year, and invest in replacements if they are not in optimal condition.

Offer training to employees

Workplace safety greatly depends on the expertise and attitude of your employees. Offer regular training to the existing workforce and hold special workshops for recruits to provide education regarding prevention and response to mishaps and spills. Establishing standard operating procedures (SOP) should be a part of the process because it enables you to keep all workers on the same page.

Provide personal protective gear

Besides training your employees, you must provide them with the necessary personal protective gear to ensure safety. Chemical plant workers require gas masks and hazmat suits to protect themselves from hazardous gasses and liquids. Also, provide proper eye protection and ear coverage. Maintaining the PPE gear in good shape is essential. Additionally, ensure they are visible and accessible at a designated place on the factory floor.

Chemical plant safety is a critical matter due to the inherent risks and hazards. Fortunately, a little effort can go a long way in securing your plant, assets, and employees. Commit to implementing these actionable measures this New Year to make your factory safe in 2023 and beyond.