Running any sort of business which relies on equipment to do its job can be a daunting prospect. Hardware will always have the chance to fail, even if you spend a small fortune on it, and there is never a good time for this sort of issue to occur. In this situation, you will be given little choice but to push towards getting started back up as soon as possible. To help you out with this, this post will be exploring some of the common practices being used to solve this issue, ensuring that you have as little downtime as possible as the result of your outages.

Redundancy

Hardware redundancy is a very big part of this process, and is something which a lot of businesses will ignore to save money. Buying more equipment than you actually need, will ensure that you always have a spare machine or two to pick up the slack when others aren’t working properly. For options like this, you don’t have to spend quite as much as you did on the equipment being used on a daily basis. As long as your backup tools can do the job, they will be good enough, and this is one of the main reasons that companies will often hold onto hardware long after they stop using it each day.

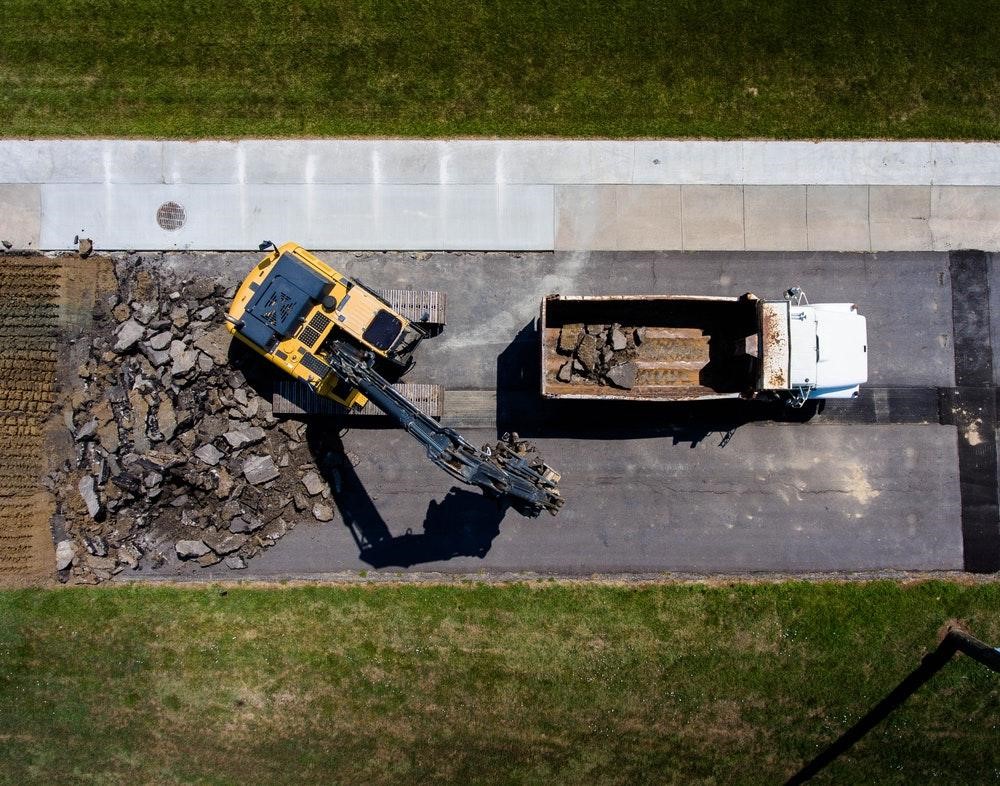

Speedy Replacements

If you don’t have a spare lying around, the next best option will be a quick replacement of what has broken down. To be able to achieve a goal like this, you will need to look into making some friends in this industry. Companies like servicetrucks.com have all of the skills and resources to help you out with this, holding loads of their products in stock, while also offering business support to help you to choose the right options for you. It shouldn’t be too hard to get a replacement, even if it is a temporary one which only needs to last until your normal equipment is back up and running.

On-Site Repairs

Finally, as the last part of this, depending on the type of equipment you use, it can often make sense to have someone in the workplace to fix this sort of issue. When it comes to computers, an IT technician will be able to solve most problems, making it cheaper to handle the job very quickly. Heavier machinery will take a little more training, but you may be able to get away with avoiding hiring them directly. A lot of repair companies can send out engineers who have all of the tools they need to complete a repair job without leaving your site. This makes the whole process much faster.

Hopefully, with all of this in mind, you will be feeling ready to start the process of protecting your company from hardware failures. It’s never easy to deal with something like this, especially in your early years, making it very important that you have the right things in place to make it easier to cope with.